Services

That Last Generations

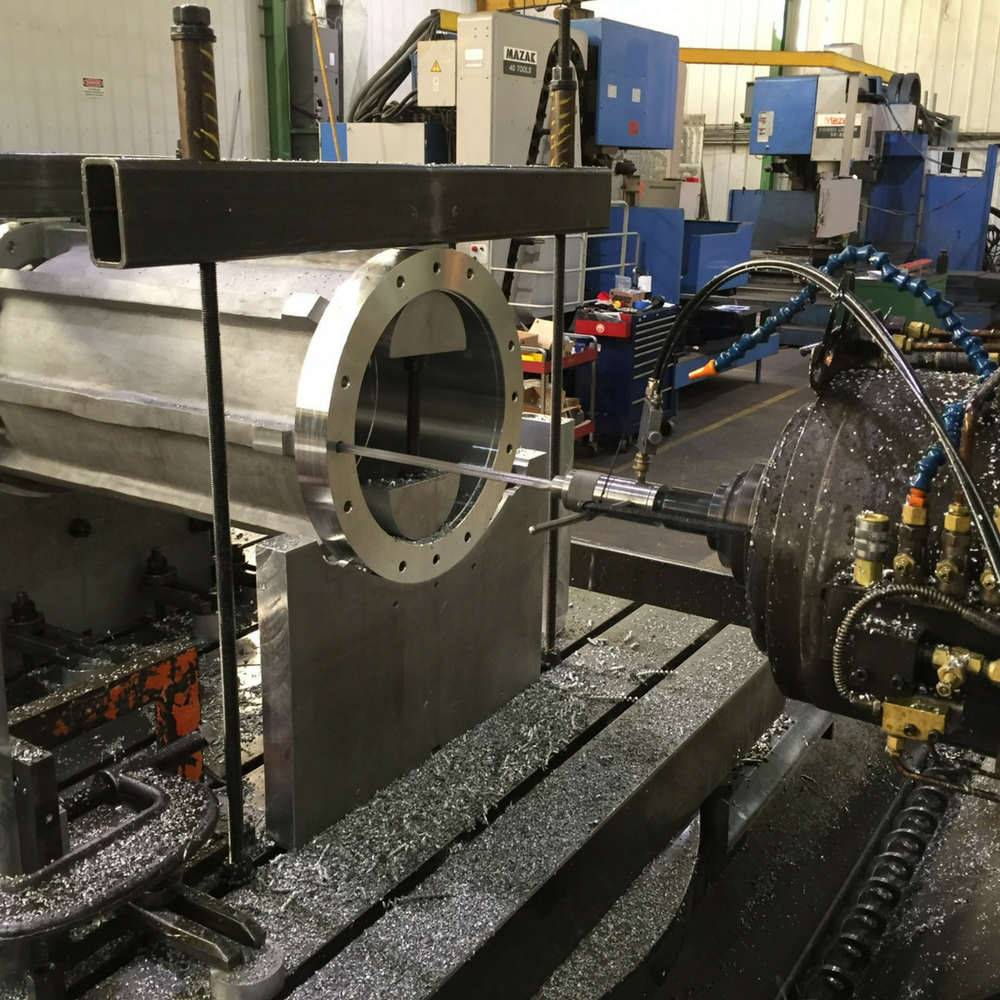

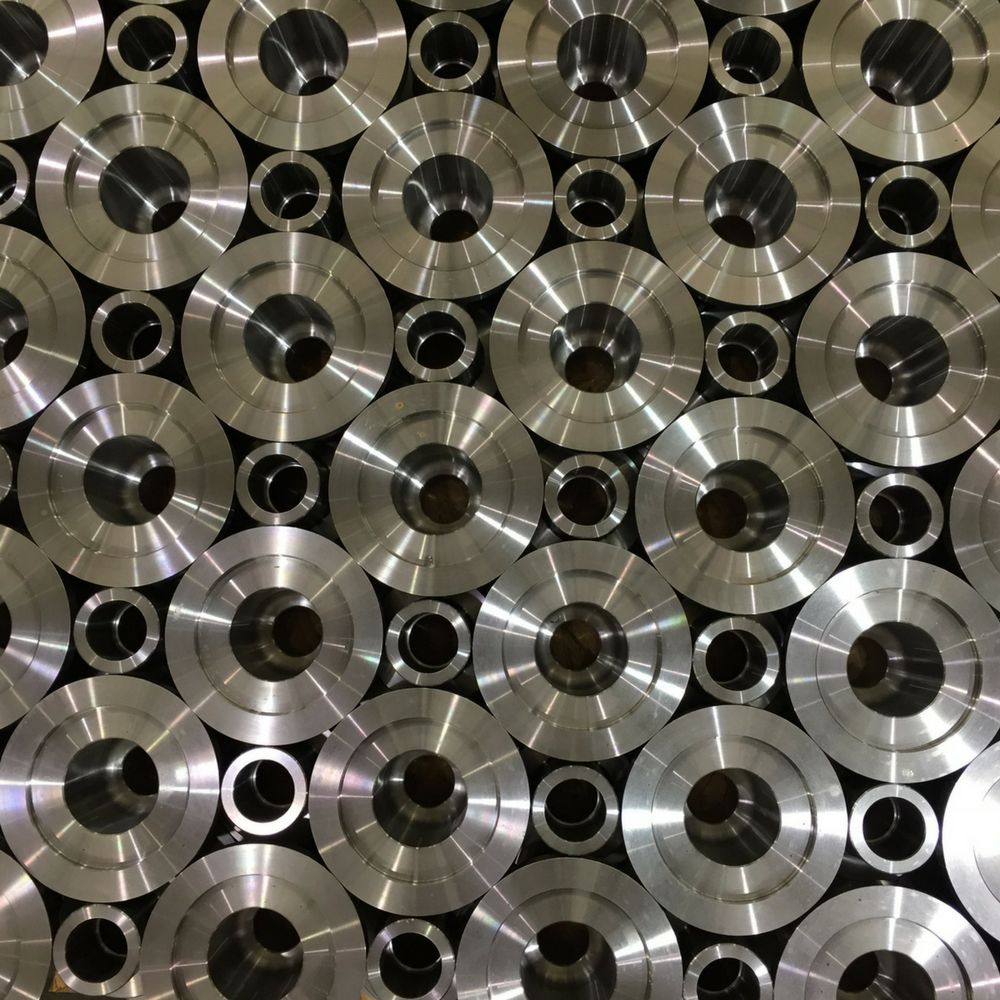

Machining

Stewart Tool provides a variety of services from rough to finish machining. Our highly skilled team provides us with a wide range of machining experience and capabilities with both CNC and manual machines.

-

CNC machining up to a 10 foot cube. Turning capability up to 8 feet in diameter.

With our in house fixture design and recognized expertise with production tooling, Stewart Tool can machine and deliver any part on time, within budget, allwhile meeting the strictest specifications in the industry.

Welding

Our ASME certified technicians possess exemplary skills and maintain rigorous proficiency under the watchful eye of our lead manager. Our capabilities in welding and fabrication set us apart from our competitors. All welding is performed by certified welding procedures with welding and processes such as SMAW, GTAW, FCAW, and SAW. With heavy duty Turning Rolls and large capacity overhead rail cranes, Stewart Tool’s weld shop is up to the task. With our new Yakasawa robotic welder, high volume production can be achieved quickly and efficiently.

Engineering

Design and Manufacturing of pressure vessels since 1998

Review of customer specifications

Participation in kick-off meetings to establish design requirements and timelines

Review WITP documentation

Creation of pressure vessel solid models, drawings, weld maps, NDE maps, etc.

Detailed project schedules

Experienced with Marine Class Societies (RINA, Lloyds Register, DNV-GL, etc.)

Familiarized with registering pressure vessel designs for exportation to other countries

Pressure Vessels

Stewart Tool Company has designed and built over 200 pressure vessels in the past 25 years

We have been involved with projects worldwide

Stewart Tool has designed and built pressure vessels to ASME Section VIII Division I & II with our U Stamp & R Stamps, EN-13445, AS-1200, AD-Merkblatt and PED 2014/68/EU

Certified to design and build CE mark pressure vessels by DNV-GL

Certified to design and build marine pressure vessels by DNV-GL Marine Class Society

Extensive experience with registering pressure vessel designs in Australia and Canada (CRN)

Proficient with Marine Class Societies (RINA, Lloyds Register, DNV-GL, etc.)

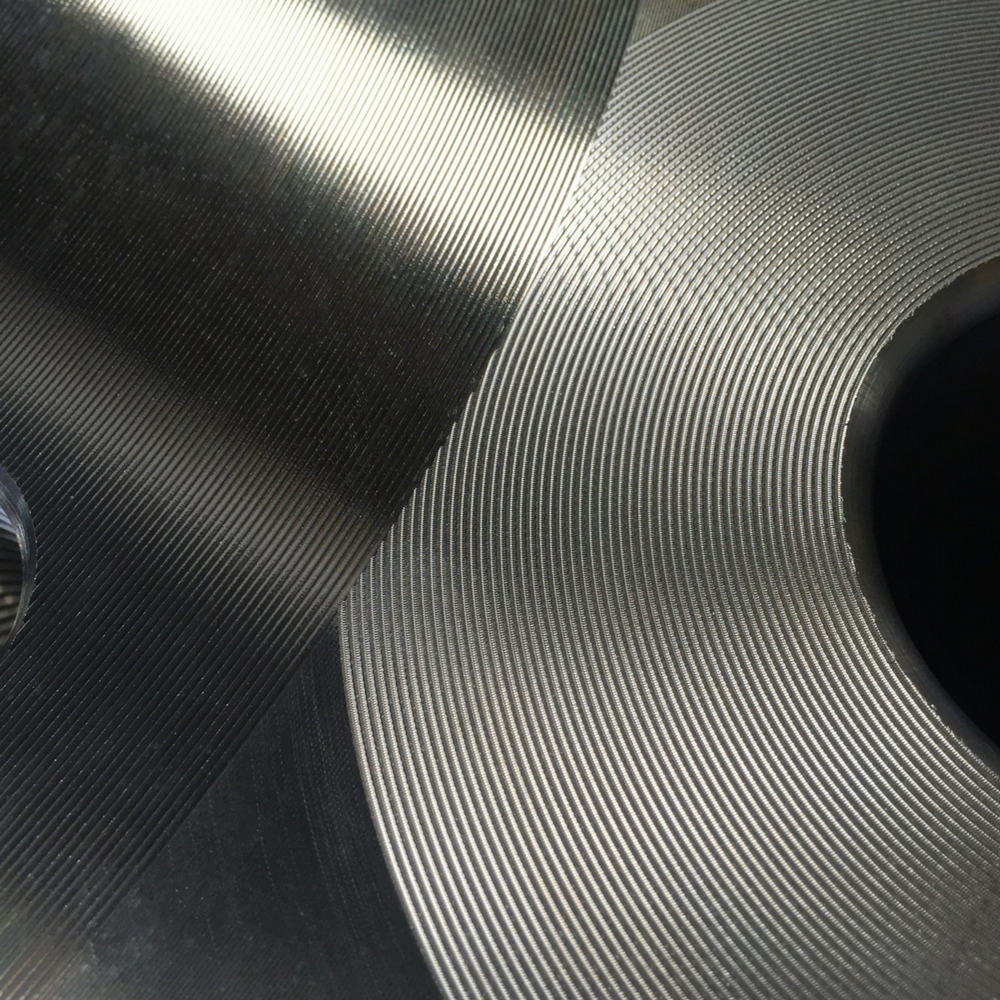

Pump Repair

10 years of experience with pump repair and rebuilds

Over 150 pumps shipped in and out for repair

Height clearance allowing vertical disassembly and assembly

Experience with Shipboard Pumps, High Pressure Pumps, Turbines, Propoline Pumps, Butane Pumps, Methane Pumps, Propane Pumps, and LNG

Stewart Tool has repaired single to 14 stage pumps up to 14' tall and over 13,000 lbs.

All rebuilding and sub-machining done in-house

Balancing of impellers and TEMs done in-house

Packaging and Shipping